Product Development

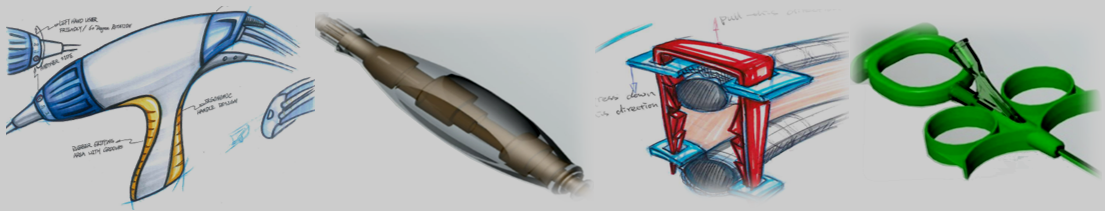

This is the first stage of the process for any company developing a new product, device, or solution. During this stage, the new product specification is defined to include functional and performance requirements broken down into critical and aspirational requirements. Initial concept options are generated, and rough sketches or CAD models are created to form a story board to convey the concept’s fit form and function.

For each presented concept we assign an investment & timeline estimate to assist in the selection process, these projections include:

- From early concept to manufacture

- Storyboards of form and function

- Finished products suitable for scale up

- Price projections

- Accredited process

- Capital investment to tool up for production

- Associated engineering investment to implement design and validate for production

- Regulatory roadmap and associated commercialisation costs/timelines

- Unit price projections for various scaled scenarios

Once the design direction is chosen a detailed 3D model is created of the selected solution.

Prototyping

This stage involves transforming your idea(s) into full-scale working models, whether it’s an original idea or a revision to an existing product. Assembly of the initial prototype is a critical step in the process as it helps to validate previous design assumptions by bringing them to life in a physical form.

Creating a suitable device that is functional is important at this stage. Throughout this phase our members apply Design for Manufacture (DFM) techniques, offer suggestions and support for design changes, which when implemented at the design phase can meet your target manufacturing costs. By implementing DFM at the design stage of a project it will in turn accelerate your time to market.

Typical development steps to prototyping:

Step 1: Define user requirements

Step 2: Concept development (ideas board)

Step 3: Select and develop concept direction

Step 4: Stage 1 prototype (demonstrate functionality)

Step 5: Concept refinement

Step 6: Stage 2 prototype (In vivo studies)

*Steps are customised to match needs.

- Concept refinement

- Design for manufacture (DFM) techniques

- Working models

- Accelerated time to market

- Accredited process

All product development is carried out in accordance with ISO13485:2012