Company Profile iNBLEX

Blow moulding is a specialist manufacturing technique that is essential to the success of the MedTech industry in Ireland. It is used primarily to make plastic bottles and containers but can also be used to make many different hollow plastic objects. However, many of the bottles and containers used by medical device, diagnostics, and pharmaceutical manufacturers in Ireland come from overseas.

That said, there are some indigenous Irish companies working hard to change this. At the forefront of this effort is Atlantic MedTech Cluster member, iNBLEX Plastics.

The iNBLEX Difference

iNBLEX Plastics specialises in the production of bottles, containers, and specialist hollow form plastic items for the MedTech industry. It primarily focuses on multinational companies with manufacturing facilities in Ireland.

While it is a MedTech industry specialist, the real point of difference between iNBLEX and the alternative of importing bottles and containers is the level of innovation and service the company offers.

“All our customers have my personal mobile phone number,” said Brendan Duggan, owner and Managing Director of iNBLEX Plastics. “They also know they can call me at any time of the day or night as delivering the highest possible standard of service is a core part of our business.”

A good example of the level of service that iNBLEX provides that many of its competitors can’t is just-in-time manufacturing. This is where medical device manufacturers only receive bottles and containers when their production line is ready for them. This speeds up production and reduces the requirement for storage space, saving money and delivering efficiency gains in the supply chain.

In addition to high standards of service, iNBLEX also focuses on delivering the highest standards of quality as well as ensuring the products it produces meet all appropriate regulatory requirements.

From Working for a Multinational to Renting Floor Space to Buying a Factory

Brendan Duggan’s background is in product and market development and engineering. He held a senior position in the medical device manufacturer Abbott Laboratories before deciding on a career change.

The prompt for this career change was an idea for a product, so he approached a local Sligo plastics manufacturer to enquire about renting some floorspace. The factory was located in a small village called Aclare in County Sligo, around 48km southwest of Sligo town close to the border with County Mayo.

While it is a rural location, it is an area that has a strong history of manufacturing as well as an established tool making industry.

Discussions with the owner of the factory developed quickly and those discussions soon led to Brendan purchasing the entire facility. That happened in 2010 and he rebranded the business as iNBLEX Plastics shortly afterward.

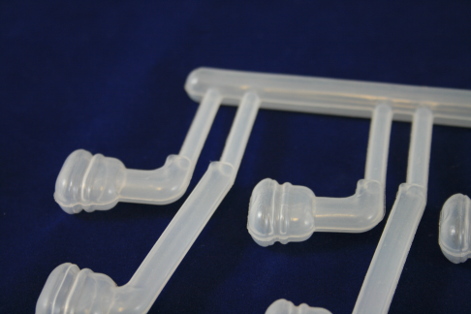

Explaining the origins of the name iNBLEX, Brendan said: “Blow moulding is our specialty, but we also do injection moulding and some extrusion work too. This is where the name iNBLEX comes from – a play on the words “injection”, “blow”, and “extrusion”.”

Range of Services

iNBLEX offers a range of other services in addition to blow moulding, injection moulding, and extrusion.

These full range of services includes:

- Extrusion blow moulding

- Injection moulding

- Injection blow moulding

- Tool making support for customer projects

- Sub-assembly, labelling, and product packaging

- Product development using 3D design, 3D printing, and subtractive prototyping

- Process validation

- Reverse engineering using 3D scanning and 3D modelling

- Management of container fluoridisation and sterilisation through external third-party suppliers

The company mostly manufactures bespoke products for specific clients, but iNBLEX also manufactures some generic products too. The range of products it produces varies considerably from client to client, demonstrating the company’s flexibility and adaptability.

Almost all its clients are in the MedTech sector, though.

Brendan said: “Previously, we had clients in the chemicals industry and the food industry, but now all but one of our clients is in the MedTech sector. The one exception is a nutrition company who we have a longstanding relationship with.”

Future Outlook

Brendan sees a range of opportunities in the market, including developing packaging solutions and other products as a substitution for those currently being imported. There are also opportunities to manufacture plastic packaging and other components for new medical device products being developed in Ireland.

“The factory here currently runs 24 hours a day, five days a week. I see significant potential for growth, however, particularly given our product development capabilities and track record of innovation. So, we have plans for expansion, including plans to move to a new manufacturing facility in 2019

“After all, medical device manufacturers in Ireland import a very large percentage of the bottles and containers they use. That alone shows the potential of the market which is fantastic for Ireland, the North West of the country, and for Sligo.”

To stay up-to-date with insights and news from the Atlantic MedTech Cluster, please follow us on your preferred social media platform:

Email signup – http://eepurl.com/dF0Y_D

LinkedIn – https://www.linkedin.com/company/atlantic-medtech-cluster/

Twitter – https://twitter.com/AtlanticMedTech

Facebook – https://www.facebook.com/AtlanticMedTechCluster/